PRECAST REFRACTORY MATERIALS

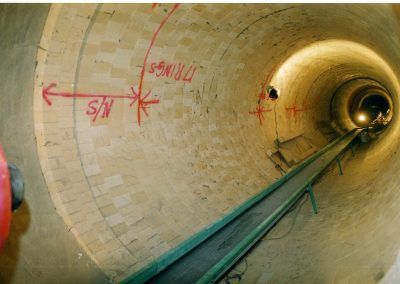

Superior Refractory Materials & Precast Shapes

Our ability to offer more than just “a bag of refractory” has contributed to our success over the years as a supplier of precast refractory materials. Through our industrial refractory services, we assist our clients in solving their refractory lining problems with solutions based on technical reasoning and sound engineering practice.

Interested in our services? We’re here to help!

Interested in our services? We’re here to help!

Have a Question? Need more information? TFL can help.