BURNER BLOCK MANUFACTURER

TFL Incorporated is an established leader in precast refractory solutions in for the demanding world of high-temp industrial processes. We have decades of experience as a burner block manufacturer.

Understanding the Purpose of Precast and Custom Burner Block Design

Burner blocks are vital in high-heat industrial applications as the initial containment and control point for the combustible fuel source within a furnace or kiln. Because of their position and purpose, burner blocks must endure the full force of the combustion process, including:

- Extreme temperatures: Furnace burner refractory can often be exposed to exceed temperatures of 3,000 degrees Fahrenheit or more, depending on the fuel and burner type.

- Thermal cycling: Furnace burners can subject refractory materials to extreme thermal stress through repeated heating and cooling cycles.

- Chemical attack: In some burner types, the combustion process releases corrosive gases and fumes that can degrade refractory materials.

- Abrasion: The fuel and byproducts within the furnace can have an abrasive effect as well, potentially wearing down the inner surfaces of the refractory burner block.

As a burner block manufacturer, we understand the harsh heating environment of furnace burner areas. Our blocks use durable refractory materials to ensure longevity and superior performance.

Many modern furnaces have unique burner configurations that require intricate block shapes for accurate installation and operation. Also, our custom solutions allow clients to select specific refractory materials for their application and industry.

Our In-House Capabilities

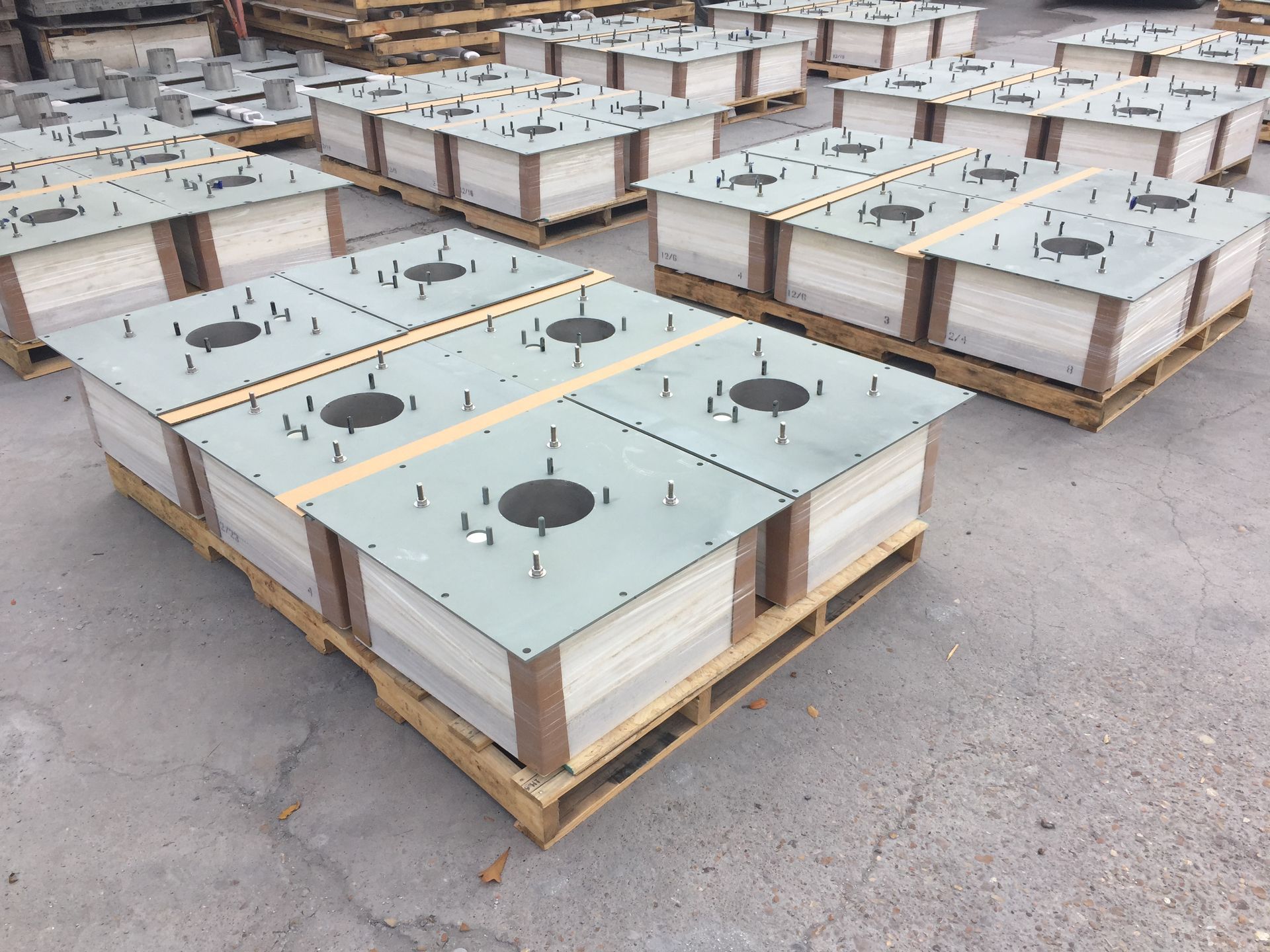

Regarding burner blocks, our

precast and

custom solutions offer unmatched flexibility. We can manufacture burner blocks to virtually any specification. We have a broad range of capabilities, catering to a multitude of diverse applications. We can create single solid burner rings or even segmented designs for larger, more complex furnace configurations. Our expertise extends to both original equipment manufacturers (OEMs) that require burner blocks for new installations and industrial facilities needing replacements for maintenance and repairs.

Choose a Burner Block Manufacturer You Can Trust

TFL Incorporated is sensitive to the demands of turnarounds and tight lead times. As a burner block manufacturer, we work closely with our clients to understand their specific needs and translate them into custom or precast solutions that integrate seamlessly with existing systems. Call our team to request a quote or inquire about service. Below are reasons to contact our team for burner tile solutions:

- Innovative Molding Techniques: TFL has developed innovative molding techniques to manufacture burner blocks to very tight tolerances. Our molding processes also minimizes stresses on the green part when it’s being removed from the mold and handled prior to firing, avoiding micro-cracking that can impact the long-term performance of the shape.

- Professional Casting: We cast burner shapes out of a variety of refractory materials, including low-cement castables, high-alumina castables, self-flowing, and rapid-heat up castables. Our customers often specify the specific material to be used, but TFL can also offer our own technical recommendation on product selection.

- Quality You Can Trust: TFL routinely produces burner tiles for original equipment burner manufacturers and furnace OEMs, as well as replacement shapes. Major refractory installation contractors, furnace suppliers, refineries, and petrochemical plants have come to depend on TFL for high-quality burner shapes and reliable delivery performance.