HEAT TREATING & FORGE FURNACE REFRACTORY SHAPES

Heat Treating & Forging Industry

These two industries are notoriously hard on refractories. High temperatures, thermal cycling, and heavy loads characterize the demands made on refractories in heat treat and forge furnaces. These furnaces also lend themselves well to the use of precast refractory.

Heat Treating and Forge Refractory Shapes

TFL manufactures precast shapes for a wide range of furnaces used in heat treating and forging. Common types of furnaces found in the heat treating and forging industry are:

- Slot forge furnaces

- Rotary hearth furnaces

- Car bottom furnaces

- Slot forge furnaces

- Rotary hearth furnaces

- Car bottom furnaces

- Box Furnaces & Box Ovens

- Tip-Up Furnaces/Clamshell Furnaces

- Drop Bottom Furnaces

- Rotary Hearth Continuous Furnaces

- Roller Hearth Continuous Furnaces

Specific applications within these furnaces where precast refractory shapes can be beneficial include:

- Burner blocks

- Jambs, Lintels, and Sills

- Curb blocks

- Pier Blocks

- Hearth shapes

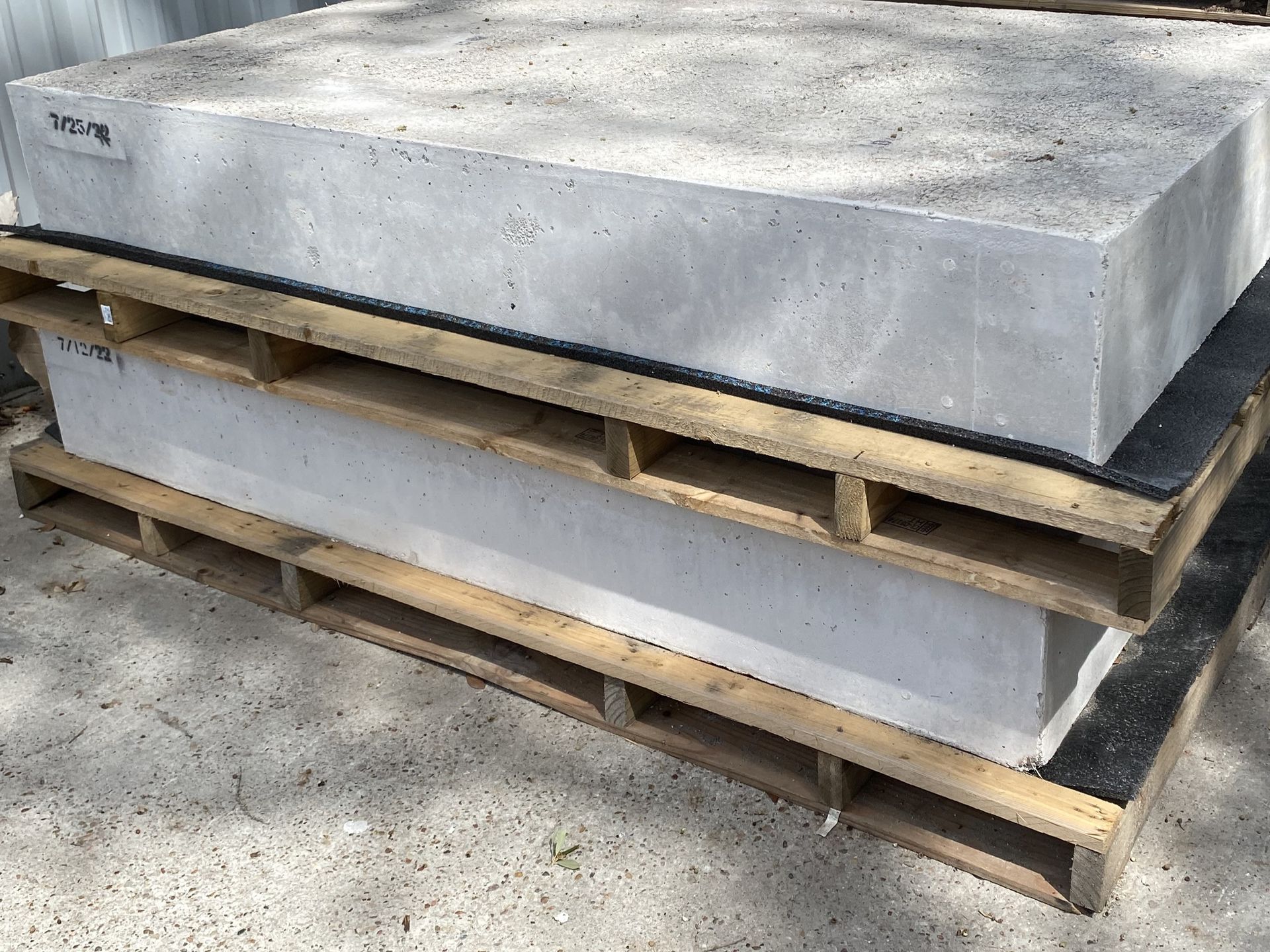

- Car Tops

- Walls

- Roofs

- Special Shapes

Benefits From the Use of Precast Refractory Shapes

There are major benefits to be gained from the use of precast refractory shapes that are related to simplified installation and repair logistics, which can lead directly to reduced costs and shorter down times. With the use of precast shapes, forming labor, materials, equipment costs, actual placement time and expense, and associated costs during form removal, curing, and cleanup are all eliminated. These costs are shifted back to the manufacturer of the shape, who can absorb them much more efficiently when spread over his overall production capacity.

Future repairs will also become much more economical and quicker to accomplish. Repair areas can often be isolated to just the immediate wear area within the boundaries of a shape. Anchor attachment points can typically be reused. Replacement shapes, purchased early and kept as spare parts on site, can be easily installed in a fraction of the time required for conventional repair methods. Repairs become more of a mechanical maintenance job, rather than a refractory installation job requiring a specialized crew and equipment.

Learn More About Precast Refractory Shapes

Through our decades as a precast refractory shape manufacturer, we've adapted precast solutions to meet the needs of most refractory applications. We routinely produce durable precast refractory shapes for a wide range of industries.

Innovation remains a core focus for us at TFL and we've made it our business to integrate the latest refractory technologies and materials into our arsenal of services. Let us help you design a precast refractory shape system for your toughest project.