What Are Refractories? Learn the Basics.

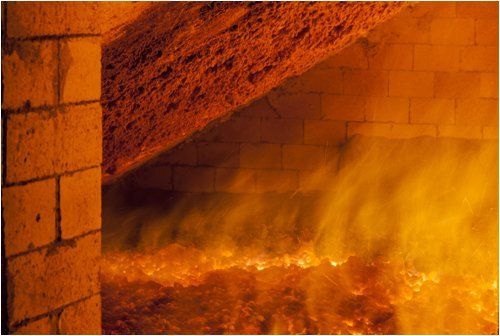

Refractories are materials designed to withstand extremely high temperatures (exceeding 1,000°F) often encountered in modern manufacturing. More heat-resistant than metals, these ceramic materials are used to line the heated surfaces found in many industrial processes.

Refractories can withstand some of the harshest conditions known to man.

Click To Tweet

What Are Refractories

In addition to being resistant to extreme thermal stress, refractories can withstand the physical wear and tear caused by chemical agents. This makes them essential in the manufacturing of petrochemical products and gasoline. They’re also crucial in industries that use extreme heat in manufacturing and production, such as steel and iron, just to name a few.

What Are They Made Of?

Refractories are made from natural and synthetic materials, usually nonmetallic. These are usually a combination of compounds and minerals such as fireclays, bauxite, alumina, chromite, dolomite, magnesite, silicon carbide, and zirconia.

What Do They Look Like?

Refractories come in all kinds of shapes and sizes. They can be pressed or molded for use in floors and walls, or made into interlocking shapes and wedges, They can also be curved to fit the insides of boilers. Some small refractory parts possess a complex and delicate appearance, while others are precast into massive blocks that can weigh several tons. The majority of refractory products are either precast shapes or unformed compositions. Then, there are refractory ceramic fibers, which resemble residential insulation but insulate at much higher temperatures. Refractory may also come in the form of powder, similar to cement, then mixed with water and applied as needed.

What Are They Used For?

From fireplace brick linings to re-entry heat shields for the space shuttles, refractories are used to contain heat and protect equipment from intense temperatures. They’re also used to line boilers and furnaces of all types, including nuclear reactors, ladles, stills, kilns, and more. The iron and steel industry uses approximately 70% of all refractories produced today.

Facing Harsh Conditions

Refractories are chosen according to the conditions they’ll face. Some applications require specific refractory materials. Zirconia is used when the material must withstand extremely high temperatures. Silicon carbide and carbon are two other refractory materials used in some very severe temperature conditions, but cannot be used in contact with oxygen, as exposure will cause oxidation and burning. Many modern technological and scientific advances simply would not have been possible without refractories.

Contact Us to learn more about refractories and their installation.

The post What Are Refractories? Learn the Basics. appeared first on Refractory Materials, Precast Shapes, and Custom Solutions.

TFL Uses Custom Molding Techniques to Make Precast Refractory Shapes With Extremely Tight Tolerances